Wood Fill PLA Pellets Tolerances Compared: Material Extrusion Report

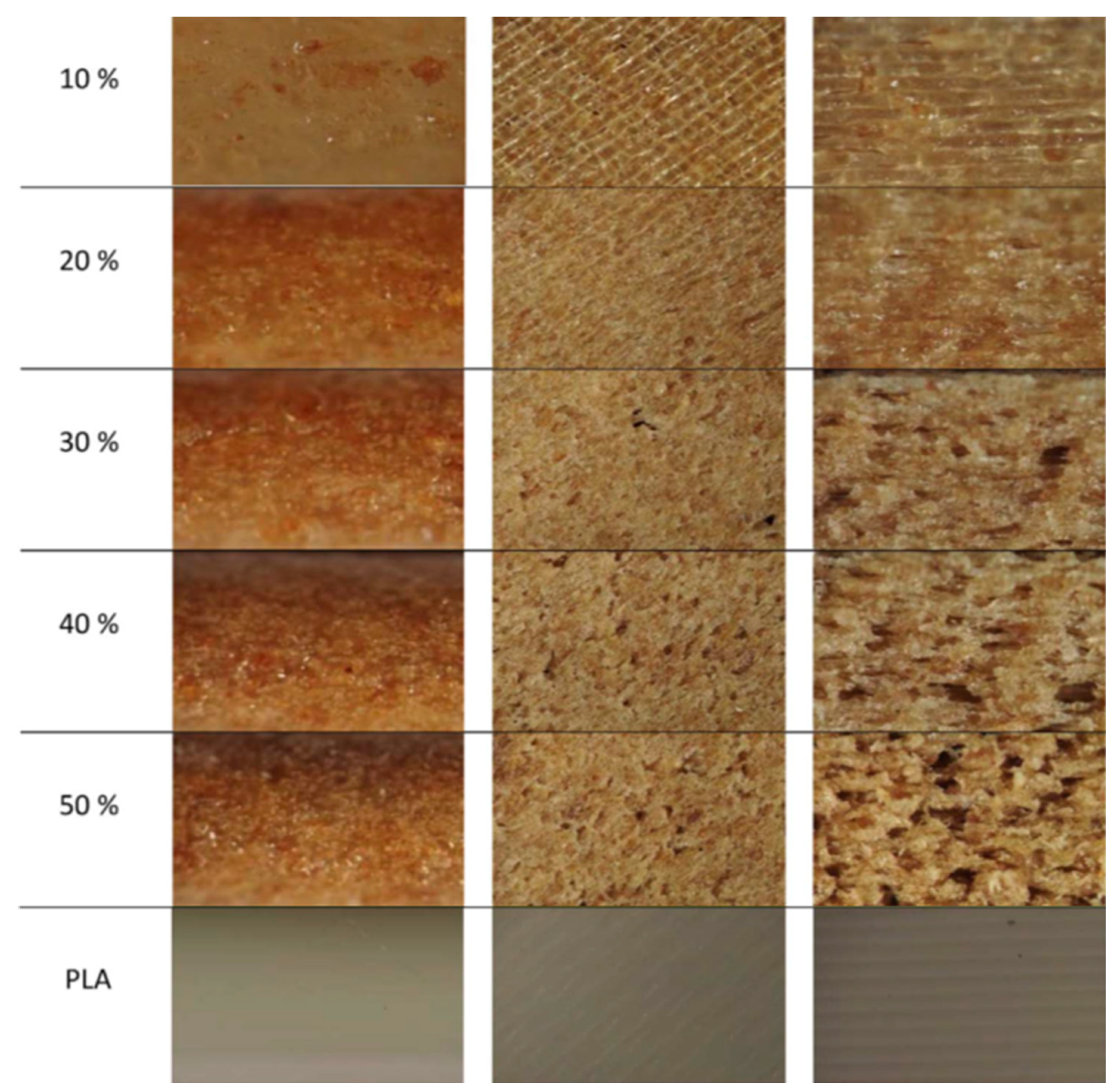

Here is one for all you additive addicts out there! Wood and plastic are often placed conceptually as antithetical materials due to their contrasting qualities- endlessly variable vs.. homogeneous and consistent, natural vs.. synthetic\, traditional vs.. futuristic. the list goes on.. In spite of this, the truth is that wood is commonly combined with different polymers as a fine dust to great effect! If you have never tried it, it is worth a try just for the smell alone- and we've got some extrusion test results that can help guide you along your way with some baseline settings for success.. Join the wood/plastic fusion revolution! Test Technician: Nasser Abdel-FatahTest Number(s): ET200831NA01-Spool1 & Spool2Plastic Name: Wood Fill PLA PelletsMSDS: N/A Need to contact ManufacturerManufacturer: Push Plastics Supplier: Push PlasticsAdditives: WoodMaterial Form: Pellets, light brown. Extrusion Test Notes Material preparation: None. Grinding: None.Drying:

Here is one for all you additive addicts out there! Wood and plastic are often placed conceptually as antithetical materials due to their contrasting qualities

Design of experiments to compare the reprocessing effect with Fused Deposition Modeling printing parameters on mechanical properties of Polylactic Acid specimens towards circular economy - Tanay Kuclourya, Roberto Monroy, Rafiq Ahmad, 2023

Wood Fill PLA Pellets Tolerances Compared: Material Extrusion Report

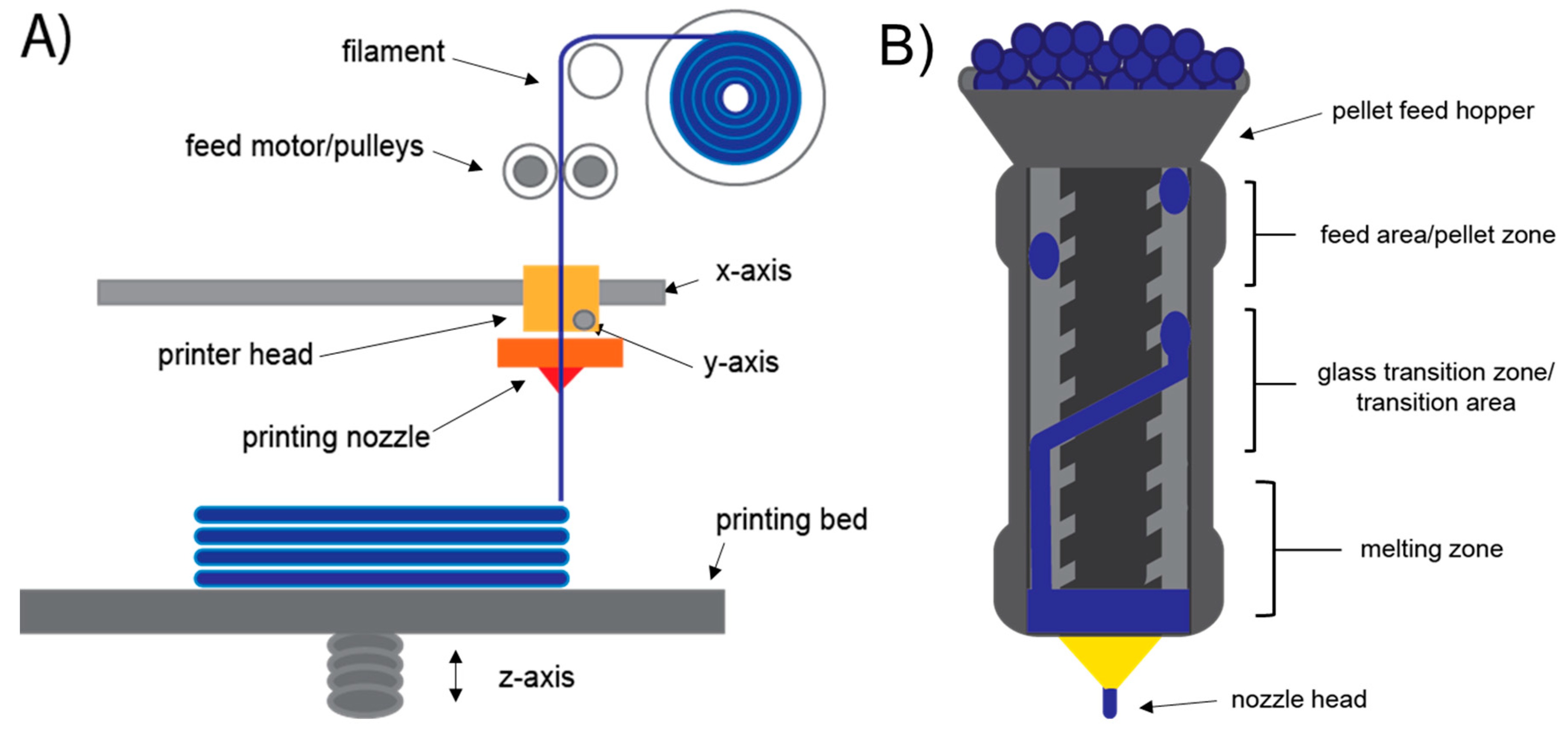

Design and development of a plastic filament extruder

Polymers, Free Full-Text

Overview of fabrication method for PLA-PHA and cellulose acetate

Polymers, Free Full-Text

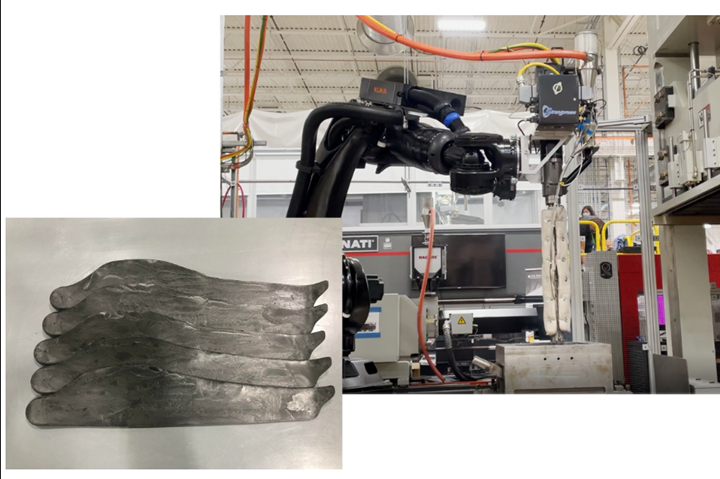

Low-void, large-scale, high-volume 3D-printed composites

Polymers, Free Full-Text

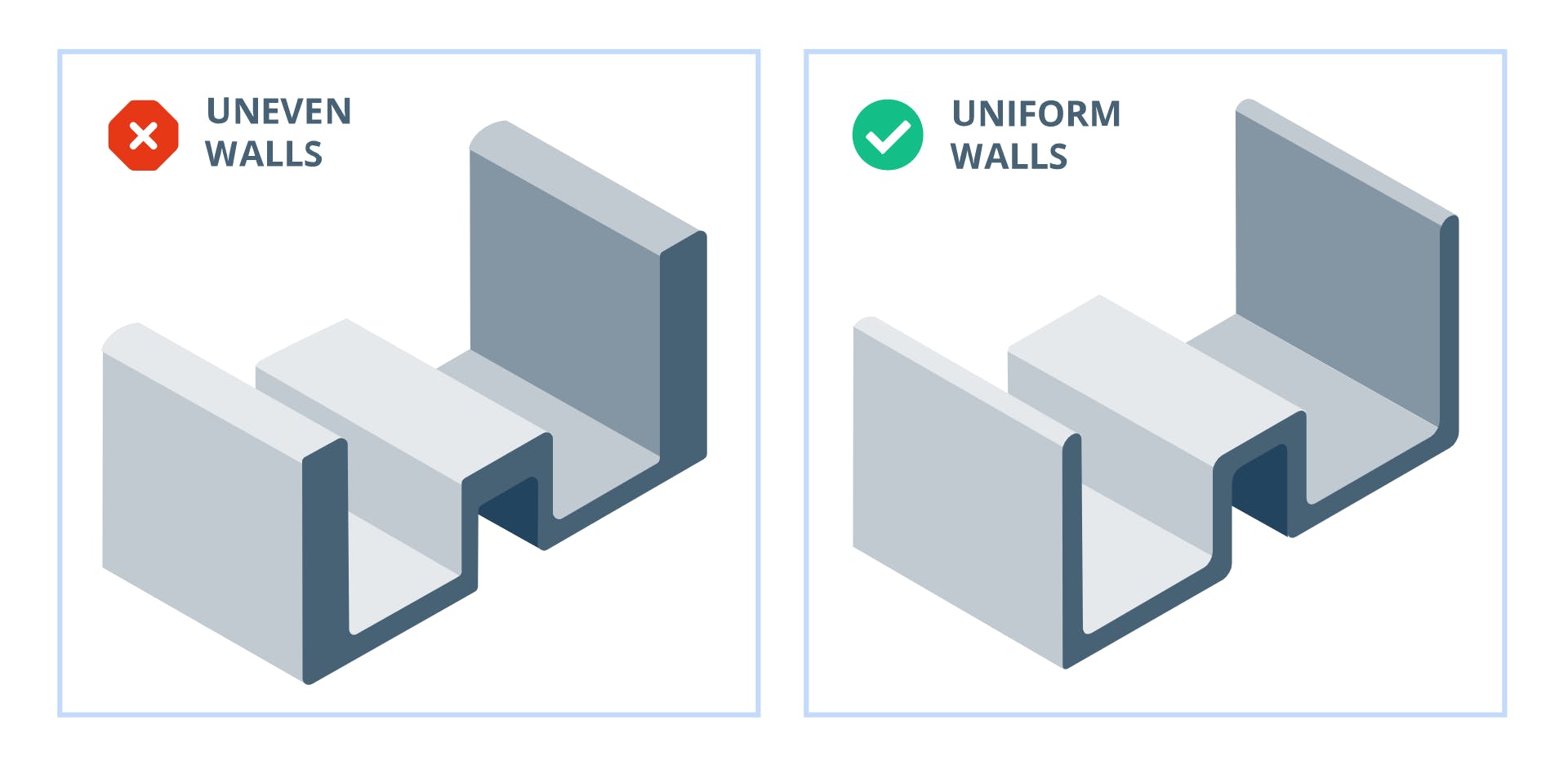

Plastic Extrusion: Definition, Purpose, How It Works, Advantages, and Examples

Upgrading from LW-PLA to LW-PLA-HT, what you need to know.

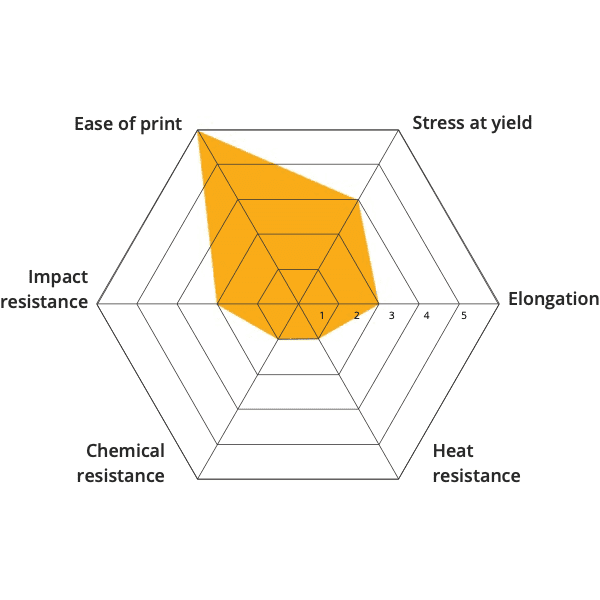

Pollen AM PLA Woodfill